BCG GAS 2000 Gas Pipe Leak Liquid Sealant

BCG GAS 2000 Gas Pipe Leak Liquid Sealant

- Brand: BACOGA

- Product Code: BCG GAS 2000

- Availability: In Stock

-

0.00€

- Ex Tax: 0.00€

Description:

BACOGA BCG® Gas 2000 is a sealing liquid designed for the subsequent sealing of threaded joints with hemp in gas inner ducts. This plastic-solvent mixture effectively seals steel pipes with threaded joints, providing a reliable solution for gas installations.

Registration Numbers:

- DIN DVGW Registration number NG-5153BL0184

- ÖVGW Registration number G 2.662

- SVGW Registration number 15-027-7

BACOGA BCG Gas 2000 Sealant User Instructions:

For mixed installations involving galvanized materials, copper, plastic, and press fittings, BCG Gas 2000 sealant does not harm plastic seals and can be used. It is also compatible with pressed pipes.

Processing:

Adhere to the requirements outlined in DVGW worksheet G 624 for the subsequent sealing of gas lines with threaded connections. Ensure sufficient ventilation during processing.

-

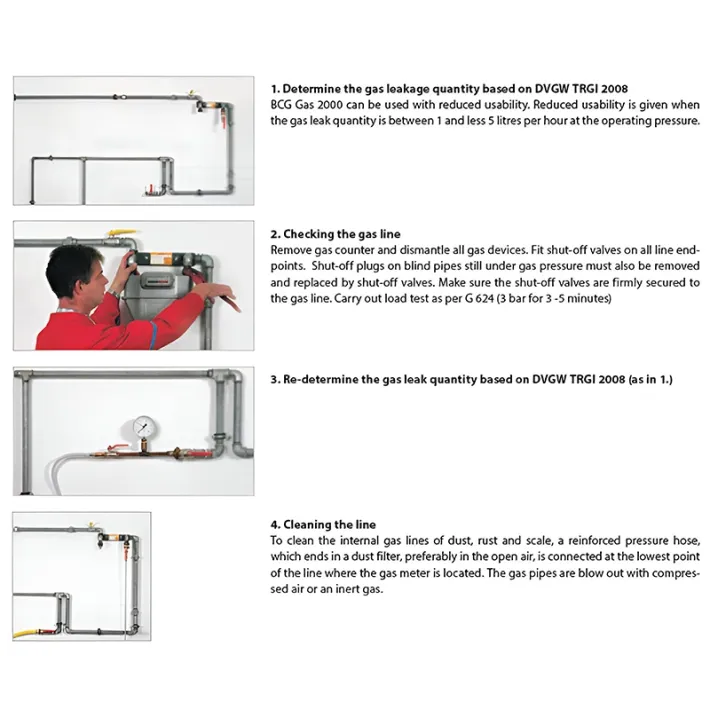

Determine Gas Leakage Quantity: Follow DVGW TRGI 2008 guidelines to determine the gas leakage quantity. BCG Gas 2000 can be used with reduced usability if the gas leak quantity is between 1 and less than 5 liters per hour at the operating pressure.

-

Check the Gas Line:

- Remove the gas counter and dismantle all gas devices.

- Fit shut-off valves on all line endpoints.

- Replace shut-off plugs on blind pipes still under gas pressure with shut-off valves.

- Ensure shut-off valves are securely fastened to the gas line.

- Conduct a load test as per G 624 (3 bar for 3-5 minutes).

-

Re-determine Gas Leakage Quantity: Reassess the gas leak quantity based on DVGW TRGI 2008 guidelines.

-

Clean the Line: Use a reinforced pressure hose, ending in a dust filter, to clean internal gas lines of dust, rust, and scale. Connect the hose at the lowest point of the line where the gas meter is located, and blow out the gas pipes with compressed air or an inert gas.

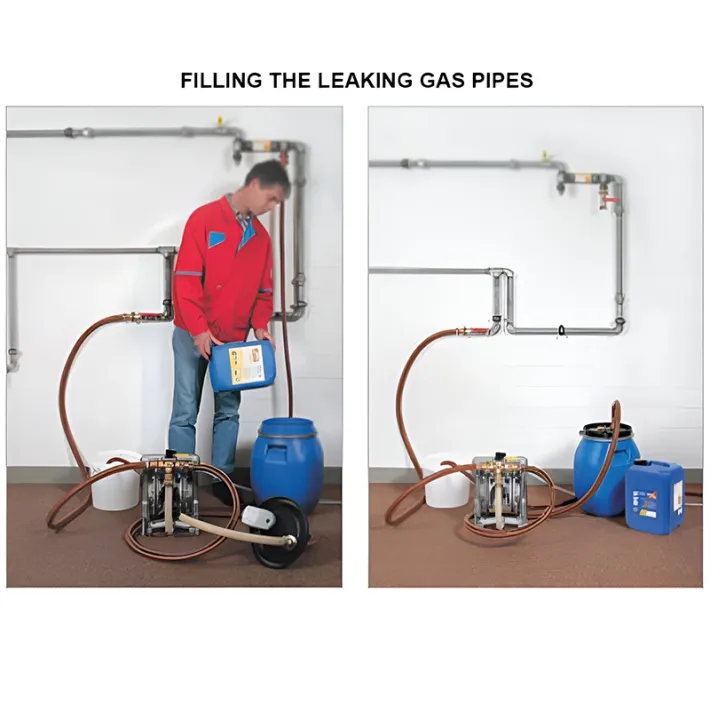

Filling the Leaking Gas Pipes:

- Shake the BCG Gas 2000 canister well before use.

- To fill leaky gas pipes, provide a compressor with a capacity of at least 250 l/min or 1 bottle of nitrogen.

- Slowly fill the line from the lowest point below the lowest shut-off valve using a membrane pump operated with nitrogen or compressed air. Ensure sufficient BCG Gas 2000.

- Purge the gas pipe system from the lowest to the highest, most remote shut-off valve. Place the end of hoses from the shut-off valves in ventilation buckets to catch residue BCG Gas 2000 during purging.

- After proper filling, charge the line with 4 bar plus 1 bar per 10 m height of the installation to be sealed. Maintain pressure for a minimum of 30 minutes.

- Connect a nitrogen pressure pad (1-2 L volume, max. 4 bar) at the high point of the line to maintain pressure during the 30-minute operating period.

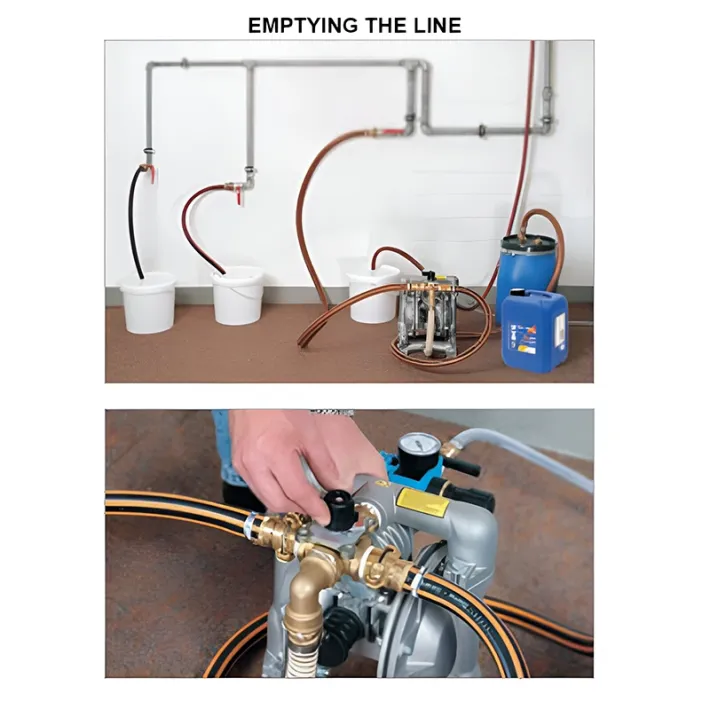

Emptying the Line:

- Carefully relax the filling pressure, then empty the line via the lowest point below the lowest shut-off valve. Open all shut-off valves from top to bottom.

- Change the membrane pump on the four-way mixer from "pump" to "suction."

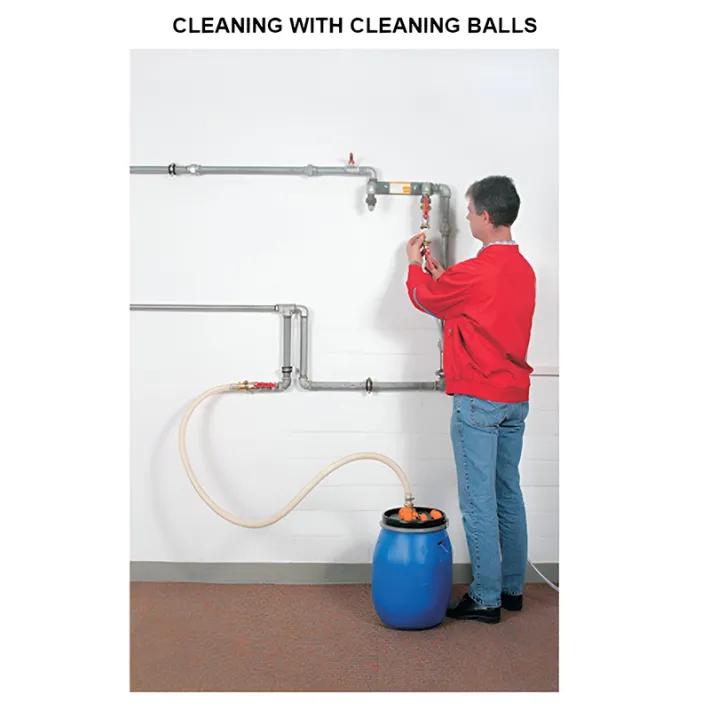

Cleaning with Cleaning Balls:

Before cleaning the gas system with the cleaning balls, disconnect the ventilation buckets and purging hoses from the shut-off valves. If no sealant runs out of the line, follow these steps:

- Use sponge rubber balls with a diameter at least 10% larger than the line cross-section.

- Introduce the sponge balls at the shut-off valve points and force them through the line using nitrogen or compressed air, starting at the highest shut-off valve.

- The balls will push the remaining sealant in front of them and transport it back into the filling container.

- Repeat the cleaning process at least twice to remove excess product residues. Depending on circumstances, this may need additional repetitions.

- The product can be reused, and contaminated product can be cleaned using a sieve.

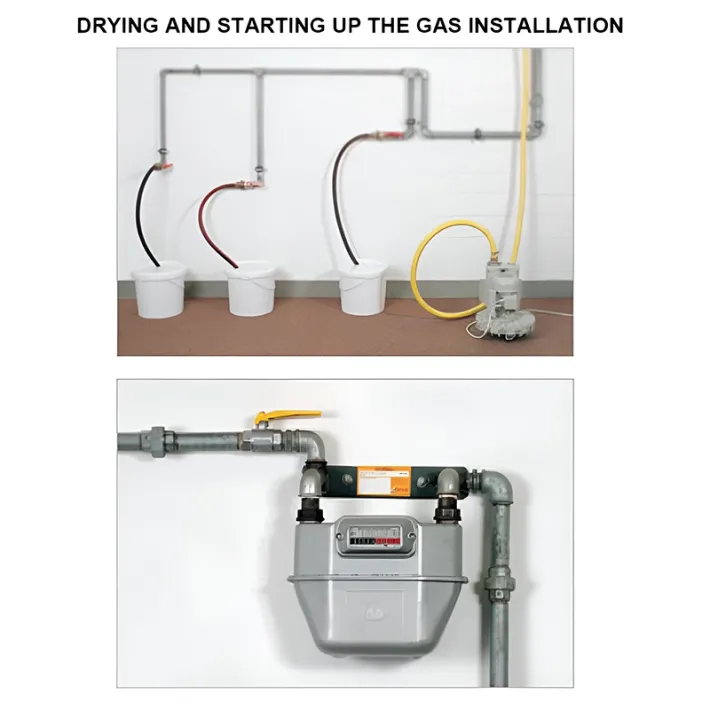

Drying:

Dry the system using a drying fan. Ensure purging hoses are secured in ventilation buckets to prevent contamination. Drying time is approximately 1 hour for 25 m pipes. Larger lines may require more time. Conduct a leak test as per DVGW-TRGI 2008 after drying.

Attention:

BCG Gas 2000 dries quickly. Cleaning is possible with water within half an hour. Partially dried product can be removed with solvent.

Starting Up the Gas Installation:

After a successful leak test, start the system following DVGW-TRGI 2008 standards. Document quality assurance measures for proper startup.

English

English Slovensky

Slovensky Deutsch

Deutsch Français

Français Italiano

Italiano Español

Español Polski

Polski Magyar

Magyar